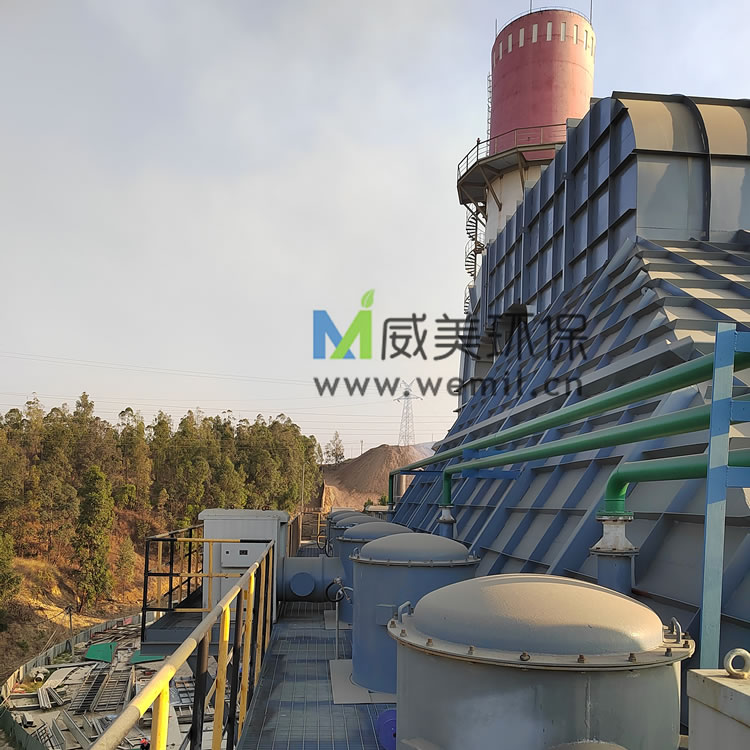

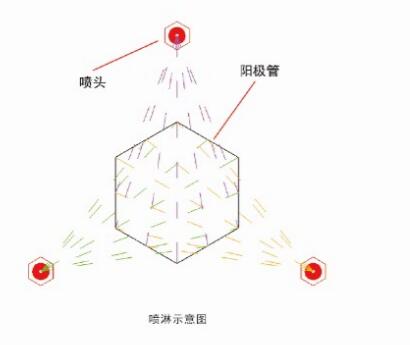

The anode module of a wet electrostatic precipitator is a fundamental component of large-scale dust removal equipment. It is mainly designed to remove harmful substances such as dust, acid mist, water droplets, aerosols, tar and PM2.5 from humid gas streams. It is applied to the advanced purification of wet flue gas in industries including coal-fired power generation, metallurgy, boiler operation, chemical engineering, waste incineration, building materials, cement production and glass manufacturing, so as to achieve clean emission standards.

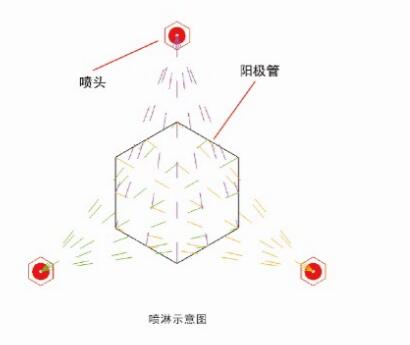

The following lists the assembly forms of anode tubes for wet electrostatic precipitators:

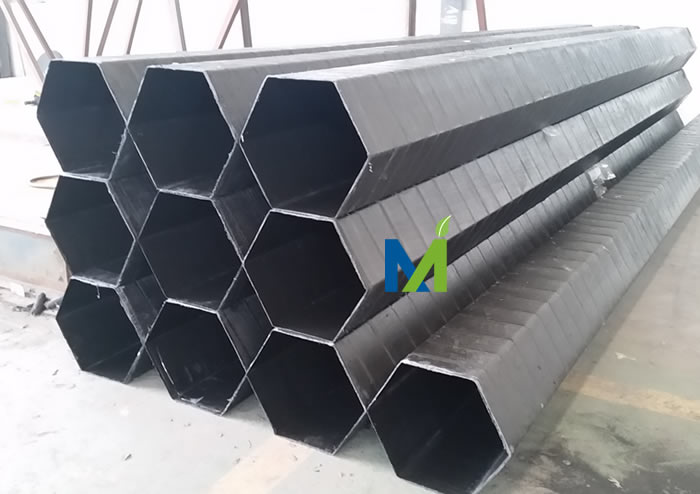

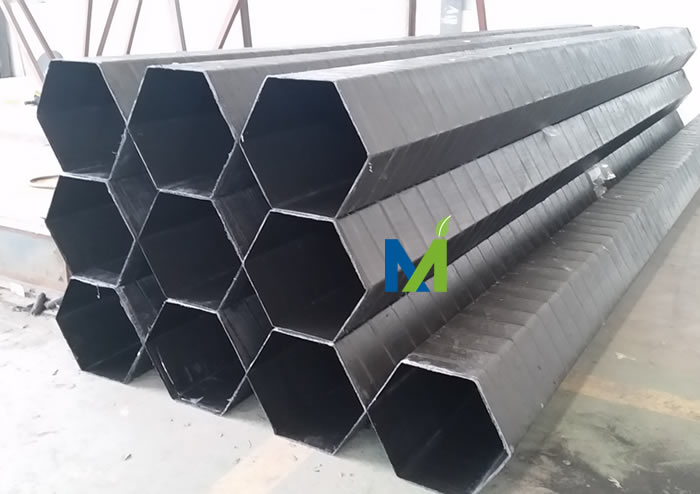

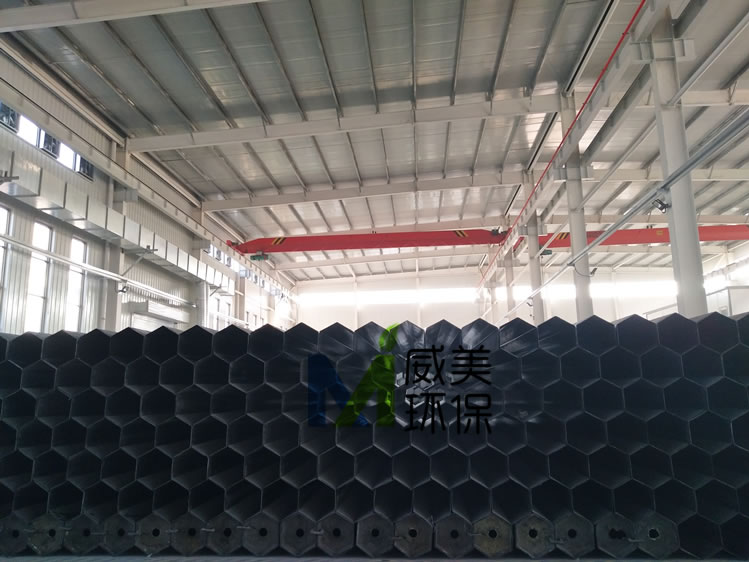

Unassembled anode tubes for wet electrostatic precipitators

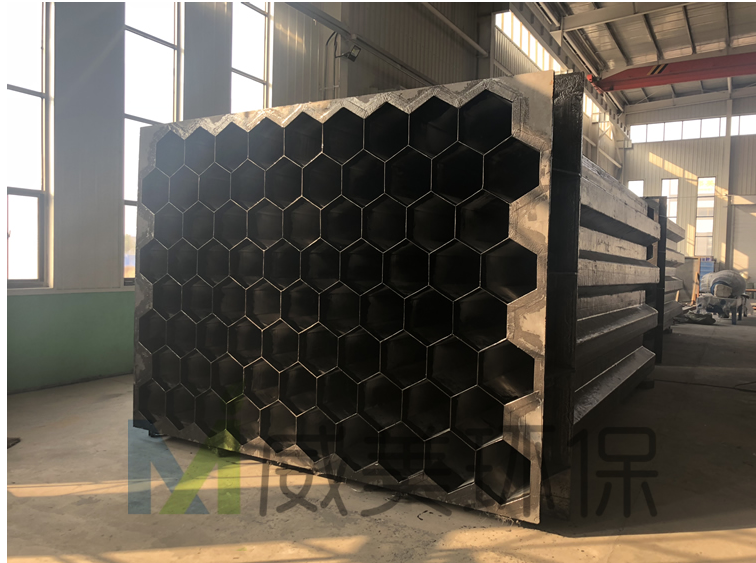

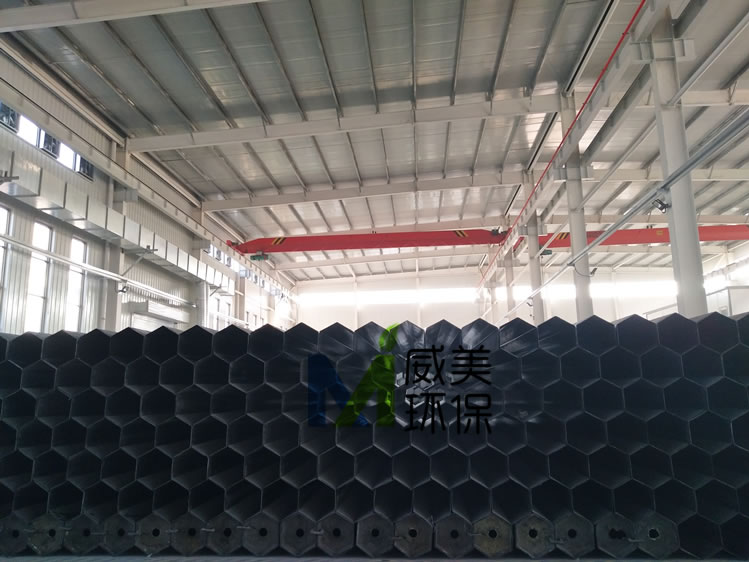

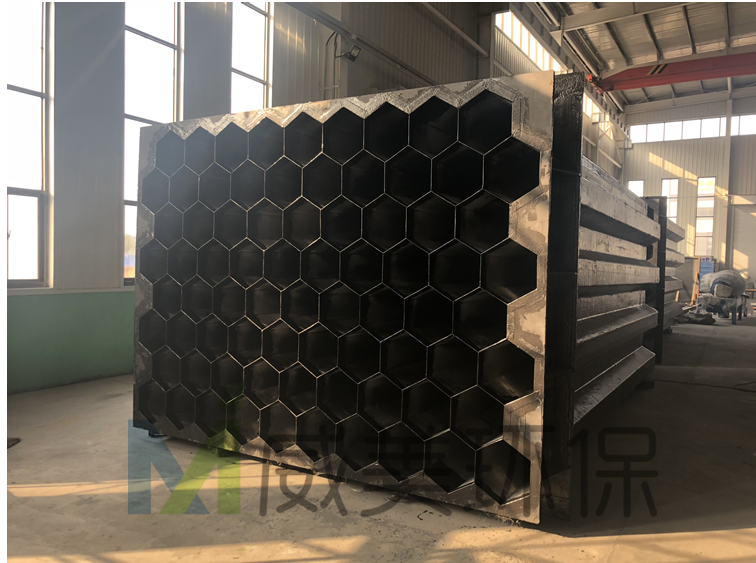

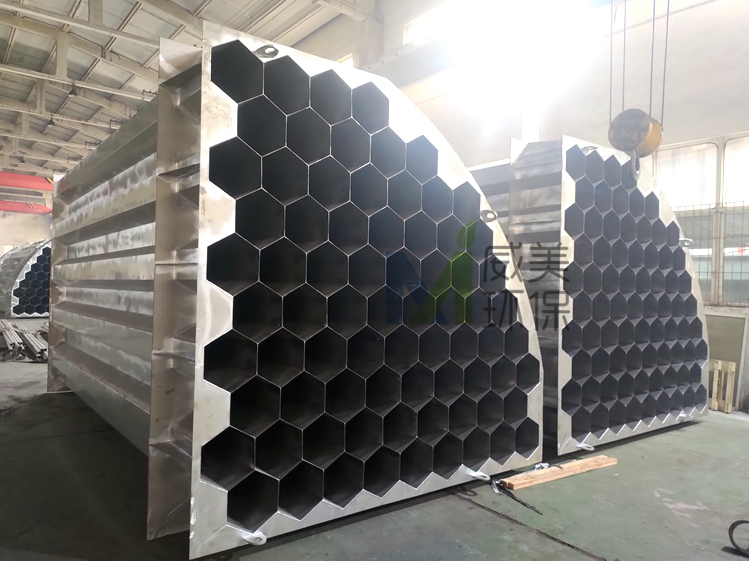

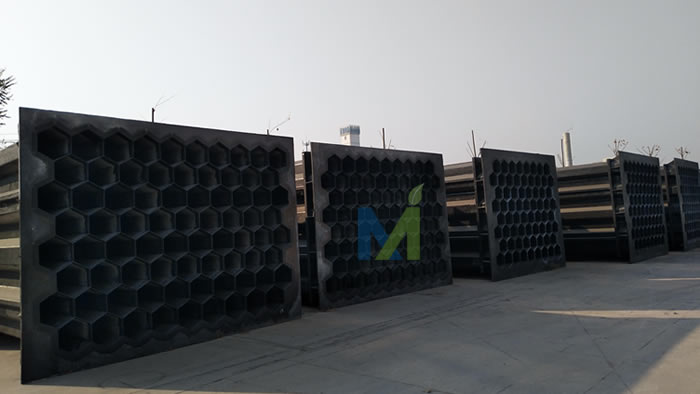

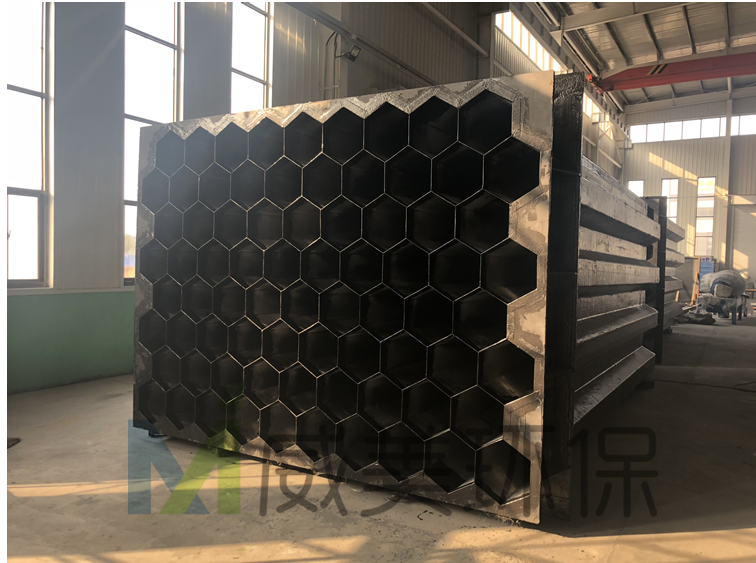

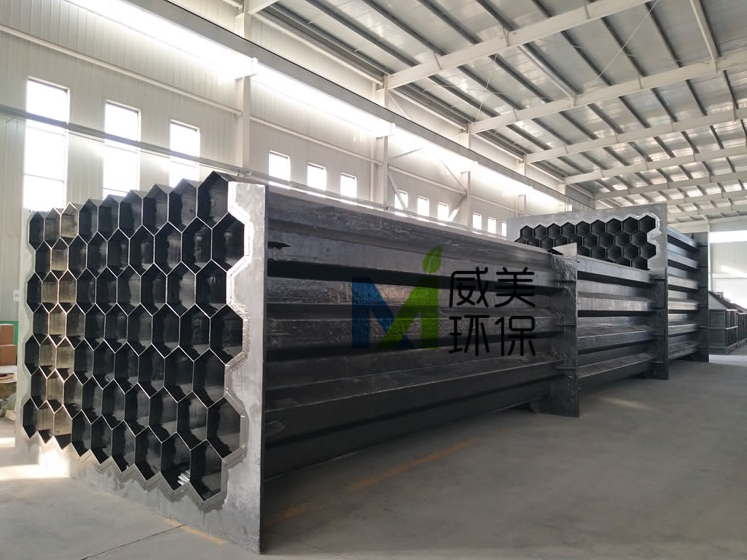

Square-assembled anode modules for wet electrostatic precipitators

Square-assembled anode modules for wet electrostatic precipitators

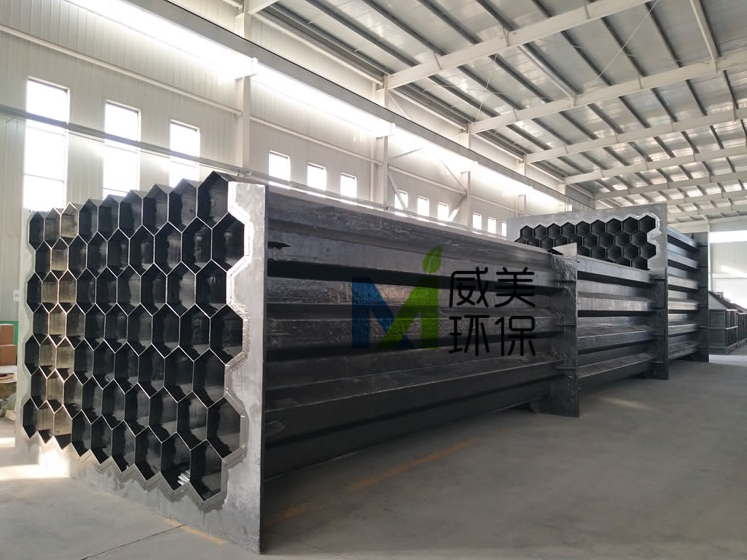

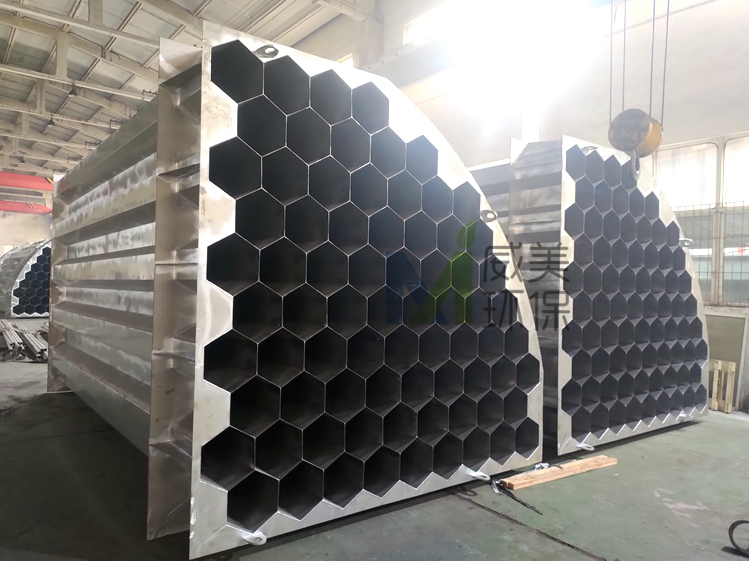

Split square anode tube bundles (divided into two halves for convenient transportation and spliced together during installation)

Anode modules for wet electrostatic precipitators with exterior anti-UV gel coat

Semicircular stainless steel anode modules for wet electrostatic precipitators

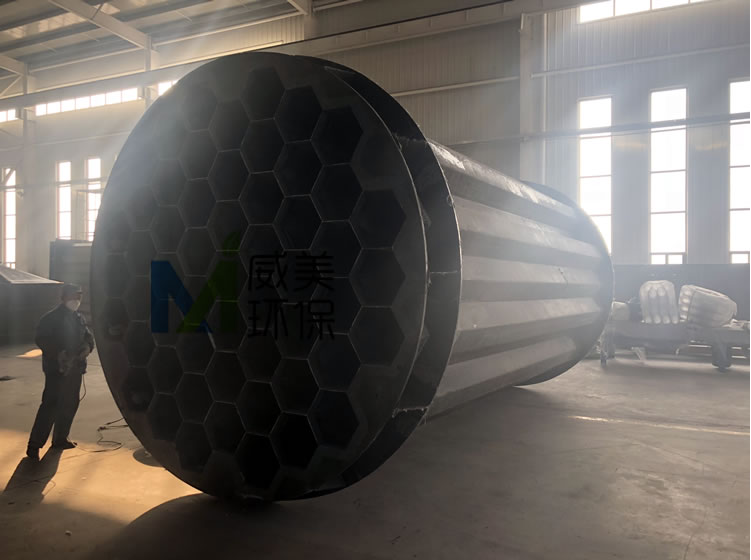

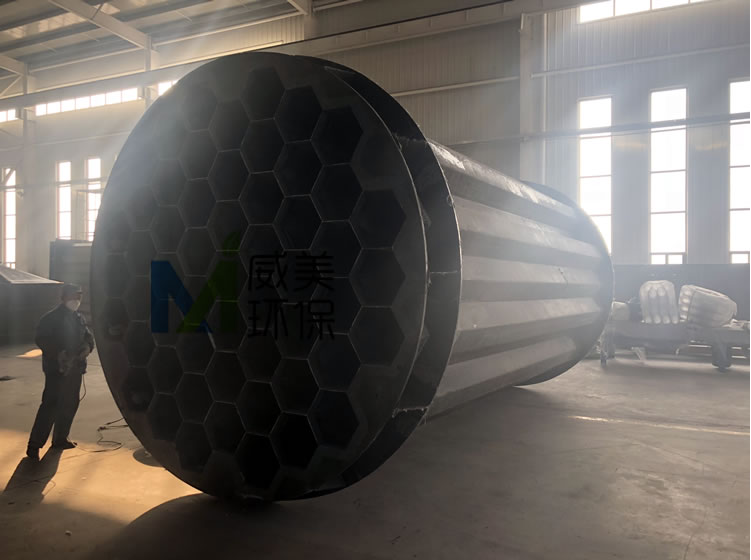

Circular anode modules for wet electrostatic precipitators

+86-18633235200

+86-18633235200