Baghouse Dust Collector for the Flue Gas Pre-treatment Unit of the 100 t/h High-temperature & High-pressure Gas-fired Boiler (540℃, 9.8 MPa) Fueled by Yellow Phosphorus Tail Gas

This unit adopts sodium carbonate (Na?CO?) as the flue gas treatment agent, and employs a baghouse dust collector for mist removal. The flue gas pre-treatment unit consists of four parts: a raw material silo, a feeding system, a mixing and drying system, and a baghouse mist eliminator. The flue gas in this project has high contents of sulfur, phosphorus and other acidic substances, so the flue gas pre-treatment unit must fully consider the corrosion caused by sulfur, phosphorus and other acidic substances. All flues in the flue gas pre-treatment unit are made of materials not lower than 2205 duplex stainless steel and 316L stainless steel.

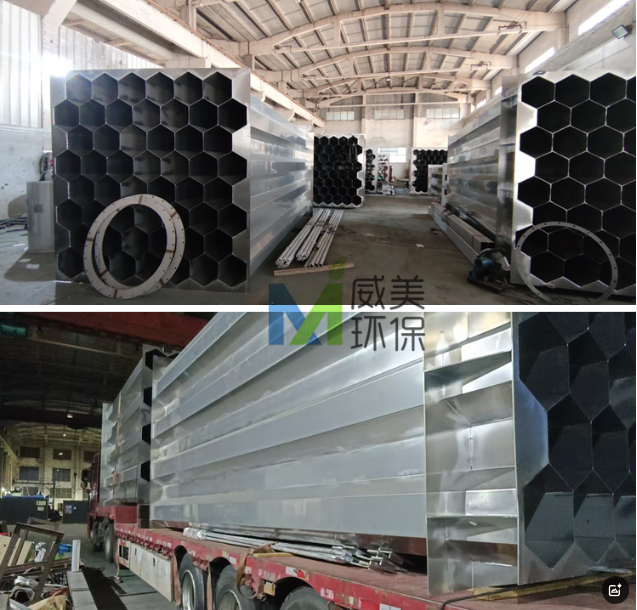

Stable Operation of the Baghouse Dust Collector (1,760 Bags) for the Comprehensive Utilization & Pre-treatment Unit of Yellow Phosphorus Tail Gas

The flue gas pre-treatment unit is composed of four parts: a raw material silo, a feeding system, a mixing and drying system, and a baghouse dust collector .

The yellow phosphorus tail gas is treated by a coal gas purification filter and then enters a gas holder. After being purified by a desulfurization device, it is fed into the 100 t/h boiler of the yellow phosphorus tail gas power generation system for combustion. The exhaust gas generated by combustion is treated through the process of flue gas pre-treatment unit + baghouse dust collector + “wet desulfurization + wet electrostatic precipitator”. SO?, NO? and particulate matter can meet the emission standards, and are finally discharged through the existing 50-meter-high exhaust stack.

+86-18633235200

+86-18633235200