The wet electrostatic precipitator is equipped with an intermittent spray method. Spraying plays a remarkably significant and effective role in improving the efficiency of the wet electrostatic precipitator, as well as maintaining the cleanliness, long-term stability and safe operation of the electric field. It is especially crucial for the safe operation of the wet electrostatic precipitator and the initial commissioning phase. All users should attach great importance to this and strictly follow the relevant requirements. For intermittent spraying, impurity-free weakly acidic circulating water or clean water can be selected.

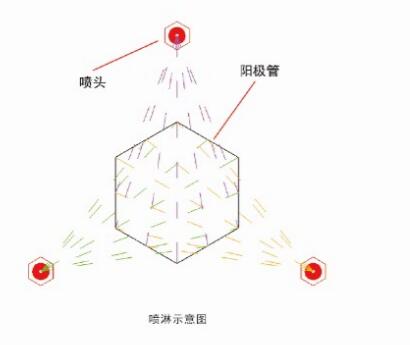

Schematic Diagram of Spraying for Wet Electrostatic Precipitator

- Clean up impurities in the spray circulation water tank, and conduct water filling and leakage testing.

- Open the inlet valve of the circulating water pump, start the circulating pump and flush the spray pipeline.

- After the pipeline flushing is completed, stop the circulating water pump and install the spray nozzles.

- Start the circulating water pump, open the pump outlet valve, and control the pressure of the wet electrostatic precipitator flushing water pipeline between 0.3 and 0.4 Mpa.

- Manually adjust the wet electrostatic precipitator intermittent spraying device to confirm that the pressure is normal, there is no leakage in the pipelines inside and outside the electric field, the spraying is uniform, and there are no obvious dead zones for spraying and washing in the electric field.

- Switch the intermittent spraying to automatic interlock control on the DCS in the control room, and verify that the actions are accurate, reliable, in-place and flexible.

- Stop the circulating water pump, close the pump inlet valve, and the commissioning of the spray system is completed.

+86-18633235200

+86-18633235200