Prior to the glass flake anticorrosion construction of wet electrostatic precipitators, a detailed construction plan must be formulated as required, a safety agreement signed, and documents including material factory quality inspection reports, certificates of conformity, shipping lists and procurement contracts provided.

The glass flake anticorrosion construction procedures are as follows:

Sandblasting

Prior to sandblasting, impurities such as rust, oxide layers and oil stains shall be removed. Sandblasting shall be performed with quartz sand or iron ore using compressed air at a pressure of 6–8 kg/cm². The surface cleanliness after sandblasting shall meet or exceed the Sa2.5 standard specified in GB 8923-88, with a surface roughness of 50–80 μm. The ambient air humidity shall be < 85%. Areas without lining or with completed lining shall be protected to prevent damage from sandblasting.

Primer Coating

The primer shall be applied within 8 hours after sandblasting. The primer coating shall use uncolored vinyl ester resin, with curing agent added and thoroughly mixed in accordance with the specified ratio. Application shall be conducted with a roller to ensure uniform coating without missing spots or sagging.

First Glass Flake Layer Application

Glass flakes shall be mixed thoroughly with curing agent in the specified ratio. Application shall be performed using a trowel and roller to ensure uniform spreading. Simultaneously, lightly roll the surface with a roller dipped in a small amount of styrene to finish the coating, with a target average thickness of 1 mm.

Second Glass Flake Layer Application

Glass flakes shall be mixed thoroughly with curing agent and color paste in the specified ratio. Application shall be performed using a trowel and roller to ensure uniform spreading. Simultaneously, lightly roll the surface with a roller dipped in a small amount of styrene to finish the coating, with a target average thickness of 1 mm.

Inspection

- Spark test (6000 V/mm)

- Thickness test (≥ 2.0 mm)

- Visual inspection

Top Coating

The topcoat material shall be mixed thoroughly with curing agent in the specified ratio. Application shall be conducted with a roller to ensure uniform coating without missing spots or sagging.

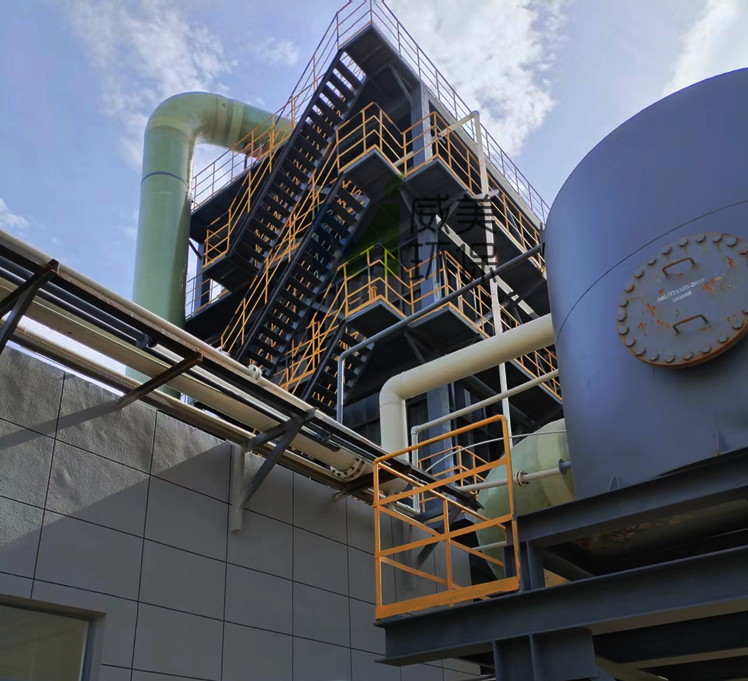

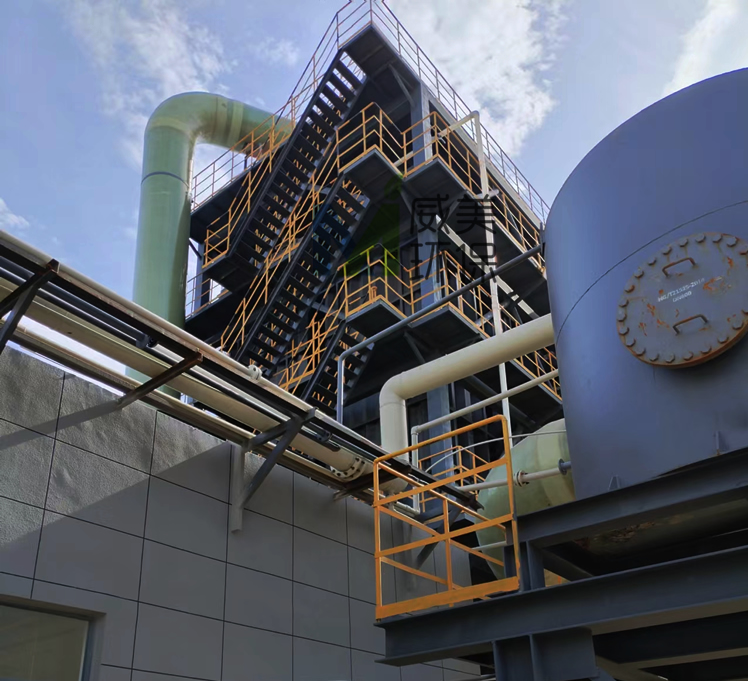

Construction Procedures for Glass Flake Anticorrosion of Desulfurization Towers

+86-18633235200

+86-18633235200