Operation Case of Calcium Chloride Tail Gas in Hubei

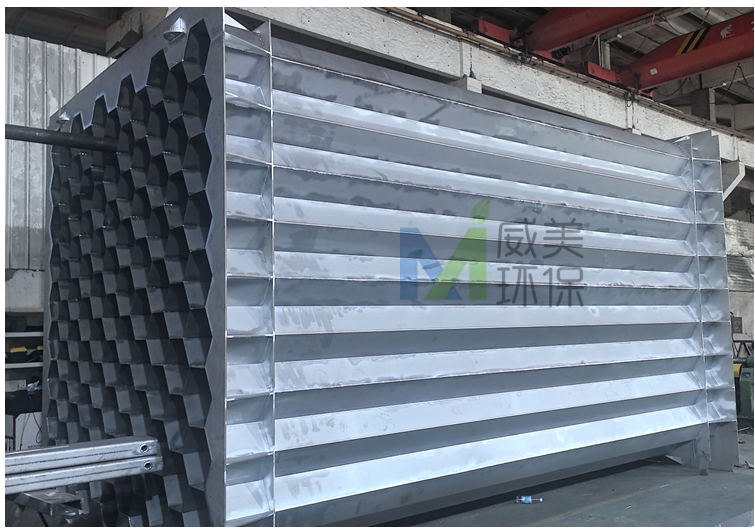

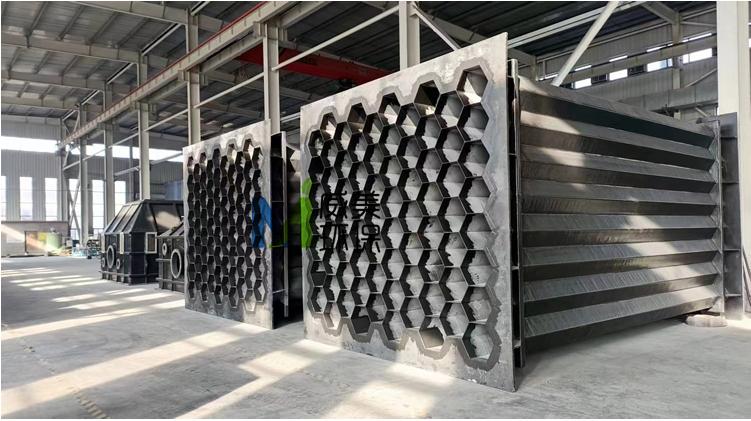

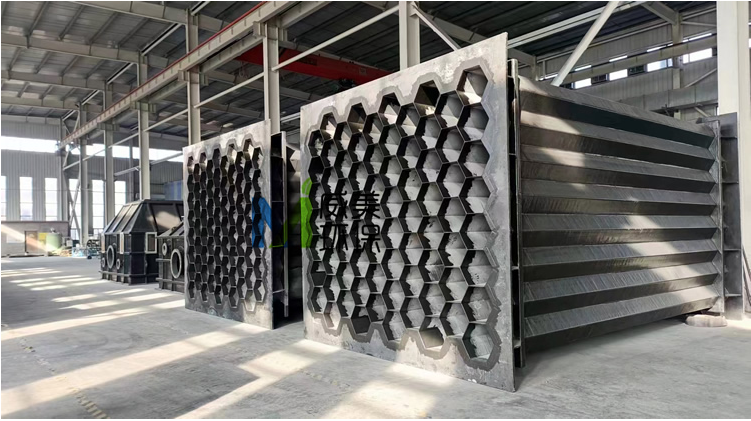

The two sets of wet electrostatic demisters are applicable to the wet electrostatic precipitator for calcium chloride drying flue gas. Hebei Weimei Environmental Protection is responsible for the functional design, manufacturing, installation, commissioning and operation of the main body of the high-voltage electrostatic demister and its auxiliary equipment system.

This wet electrostatic demister has a flue gas treatment capacity of 180,000 m³/h, with the inlet flue gas dust content (particulate matter) ≤ 200 mg/m³ and flue gas temperature ≤ 50℃. The air inlet and outlet of the demister are arranged in a bottom-in and top-out mode, and the designed flow rate of the demister is 1.1 m/s. The required dust emission concentration of the final product ≤ 20 mg/m³ has been achieved up to standard at present.

Wet Electrostatic Precipitator for Calcium Chloride Drying Flue Gas Treatment in Yichang, Hubei: Air Inlet and Outlet Arranged in Bottom-in and Top-out Mode

Operation Performance of Calcium Chloride Tail Gas Treatment in Shandong

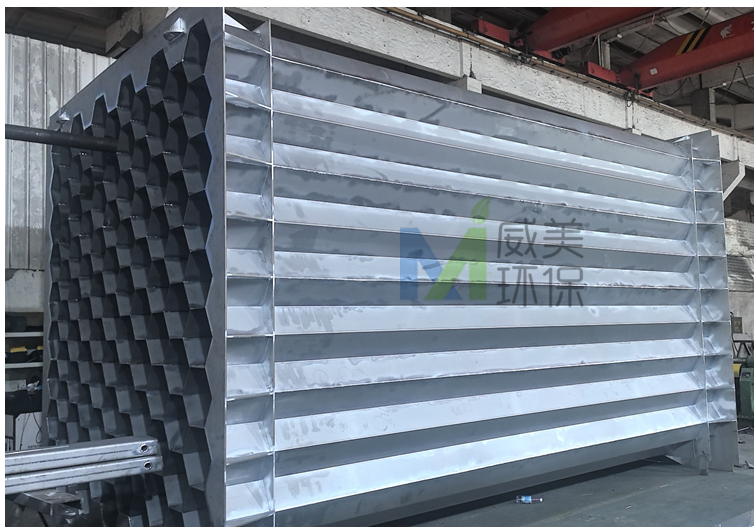

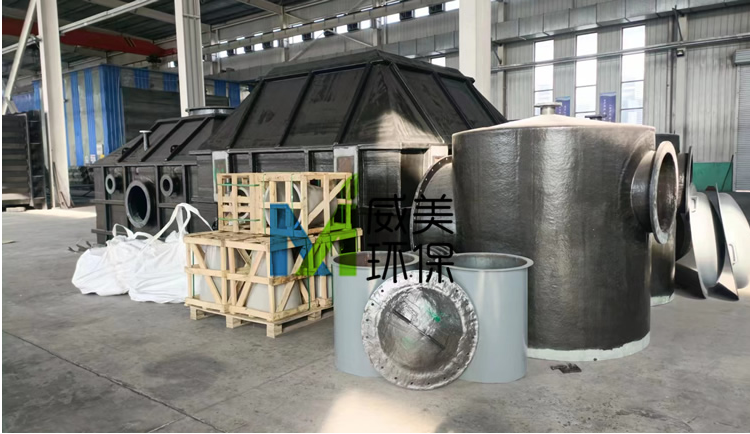

The first wet electrostatic precipitator for upgrading and reconstruction of calcium chloride production line in Shandong Project

The customer is engaged in the chemical production of sodium metabisulfite, sodium bicarbonate, calcium chloride and magnesium chloride. Among them, the calcium chloride production line is in urgent need of environmental protection upgrading and reconstruction. The flue gas flow rate of the demister in this production line is 40,000 m³/h, the inlet flue gas temperature is below 60℃, and the airflow direction is bottom-in and top-out.

The one close by is the second unit, and the one in the distance is the third unit of wet electrostatic precipitator for flue gas deep purification, showing the treatment effect of calcium chloride tail gas.

Treatment Effect of the Fourth Wet Electrostatic Precipitator for Calcium Chloride Tail Gas Treatment

+86-18633235200

+86-18633235200