Boiler flue gas in cane sugar refineries is generally characterized by high moisture content and high dust density. For the treatment of such flue gas, the gritstone water film demisting technology can be adopted. It is a wet demisting process based on gritstone, configured as a "vertical/horizontal Venturi + cyclone water film/cyclone plate demister". This technology boasts advantages such as low investment, simple maintenance and long service life. Flue gas treated by this technology could basically meet the previous old emission standards; however, with the upgrading of emission requirements to the current new standards, this technology can no longer satisfy the existing compliance criteria.

At present, three technologies are worthy of exploration, namely bag-type demisting technology, electrostatic-bag hybrid demisting technology and wet electrostatic precipitator technology. Each of these three demisting technologies has distinct advantages: bag-type and electrostatic-bag hybrid demisting technologies feature high demisting efficiency, but they entail high operating costs and have a short service life. In contrast, wet electrostatic precipitator technology is highly practical and easy to operate, yet it needs to be combined with other technologies to exert its optimal performance. The better the water droplet atomization effect and the larger the dust particles, the more prominent the final treatment outcome will be.

Up-to-Standard Emission of Flue Gas in Sugar Refineries via Gritstone Water Film Demisting + Wet Electrostatic Precipitator

Performance Demonstration of Wet Electrostatic Precipitator for Boiler Flue Gas in Sugar Refineries

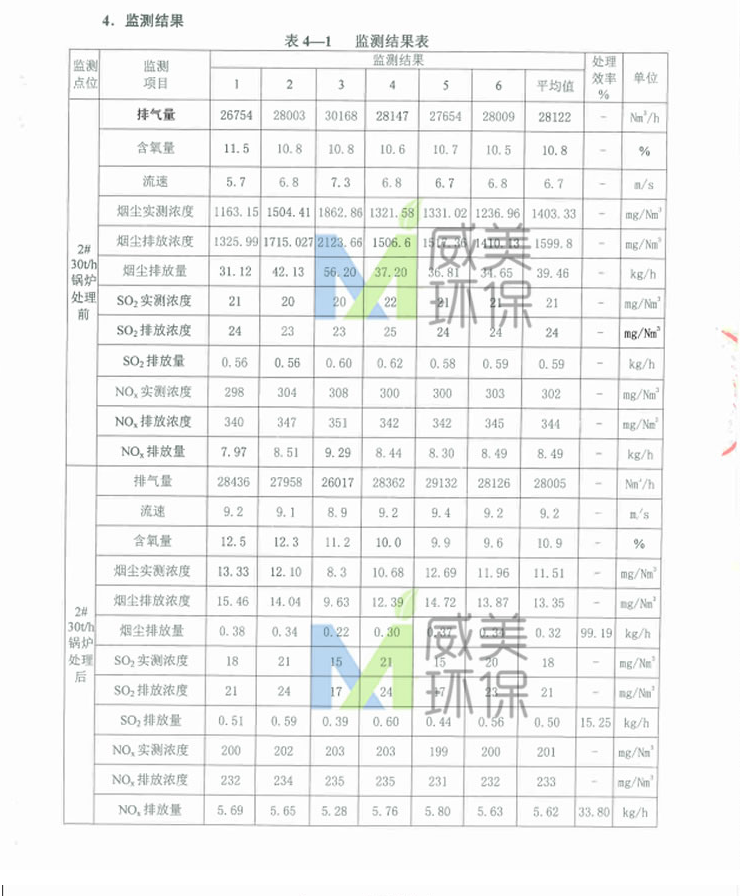

Tail Gas Monitoring Data from the Wet Electrostatic Precipitator Project for Tail Gas Treatment in Sugar Refineries

Tail Gas Monitoring Data from the Wet Electrostatic Precipitator Project for Tail Gas Treatment in Sugar Refineries

+86-18633235200

+86-18633235200